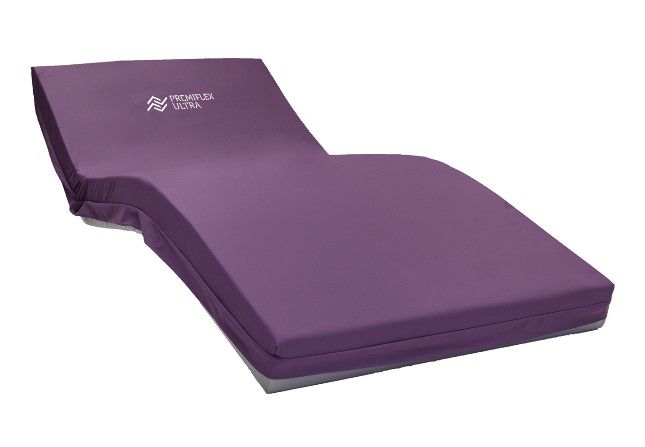

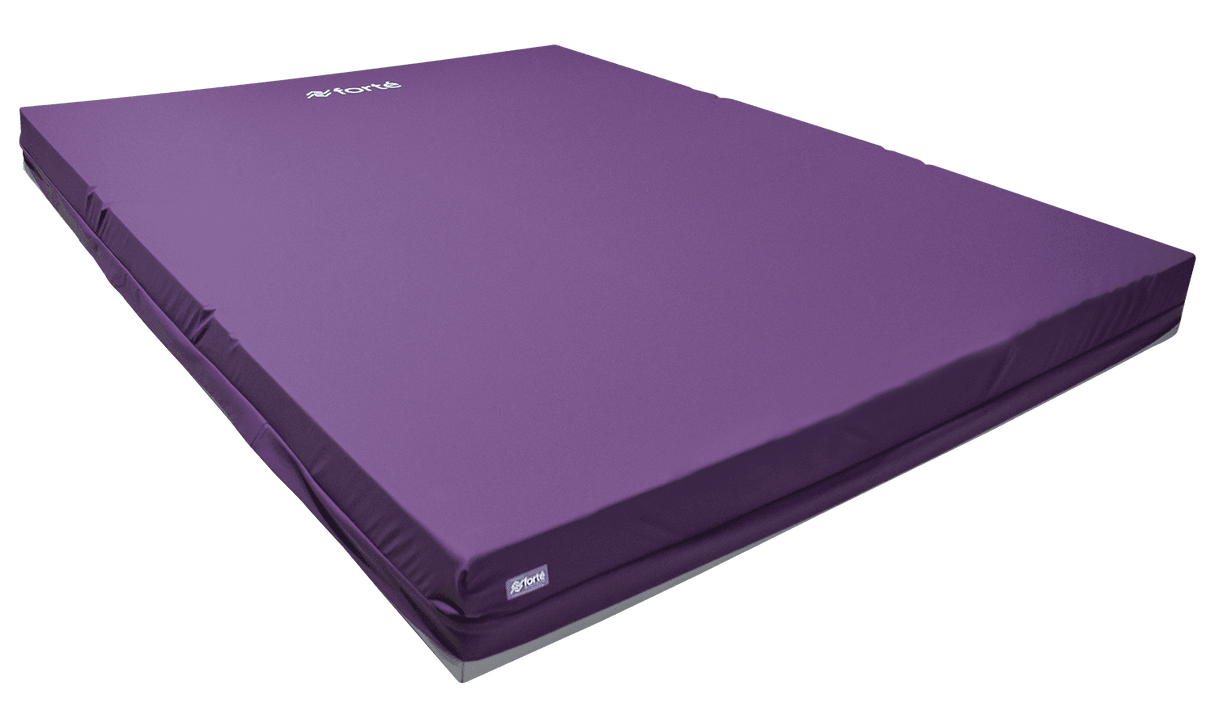

Forté Premiflex Ultra Covers Double

Forté Premiflex Ultra Covers Double - Single is backordered and will ship as soon as it is back in stock.

Couldn't load pickup availability

Delivery and Shipping

Delivery and Shipping

Boxed Metro Delivery within 10km of the capital city:

For metropolitan areas, we offer boxed delivery, which may require assembly depending on the product. If assembly issues arise and a technician is needed, customers may incur a call-out or service fee. Free Boxed Delivery is available for orders exceeding $500 within Metro areas (within 10km of the capital city), excluding assembly and setup. Metro Pre-Assembled Delivery is an alternative option if assembly is required.

Pre-Assembled Delivery:

Customers can opt for fully assembled and functional product delivery. This option is particularly beneficial for the elderly or those who may struggle with assembly. There is an additional $300 charge for in-home fitting of hospital beds/riser recliner chairs. Please note, in certain rural areas, assembly of large items may not be feasible.

We aim to cater to all regions across Australia and will make every effort to find suitable solutions for our customers.

For inquiries, reach out to us at 1300 232 273 or via email at Hello@ahealthcare.com.au.

Description

Description

The Forté Premiflex Ultra Breathe Covers Range builds on the attributes of the Premiflex range and delivers superior infection control and overall mattress longevity.

Payment & Security

Payment methods

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.